About this Post

After reporting on the INA219 in my last post, I would like to introduce the INA226 and my associated library INA226_WE in this article.

In a first approximation, the INA226 is an INA219 with alarm function, which is particularly well suited for monitoring currents. In addition, the INA226 can be used on both the high-side and the low-side. I will come back to other differences to the INA219 in the course of this article.

First of all, I will deal with the measuring principle and the technical data. Then I present the library with its numerous example sketches. Finally, the last part is for those who want to go deeper. It deals with the inner details of the INA226 and the library.

The measuring principle

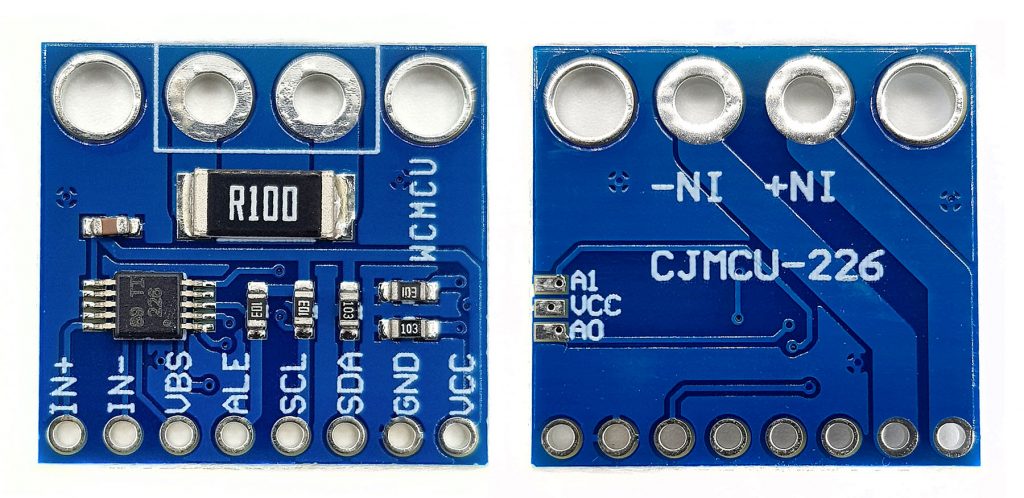

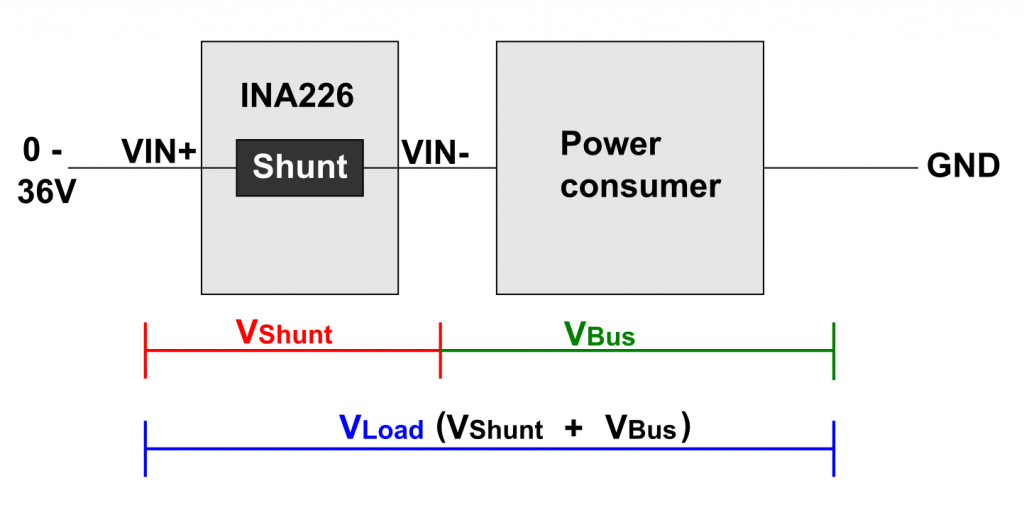

Basically, the INA226 works the same way as the INA219. You conduct the current to be measured via the terminals IN+ and IN- through a shunt (current resistor). An A/D converter measures the voltage drop across the shunt and the INA226 calculates the current from this.

If you use the bare INA226 (the eight-pin IC on the module), then you are free to choose the size of the shunt. The modules have a shunt of 0.1 ohms. In any case, this applies to all models that I have dealt with.

In addition, the INA226 measures the bus voltage, i.e. the voltage drop across consumer. This happens between VBUS and GND. The INA219, on the other hand, measures the bus voltage between IN and GND. That’s why you have to place the INA219 before the consumer (high-side). With the INA226 you are more flexible; you can use it on the high-side as well as on the low-side.

The INA226 calculates the power from the current and the voltage drop across the consumer. It writes the measured values to its data registers, from where you can query them via I²C.

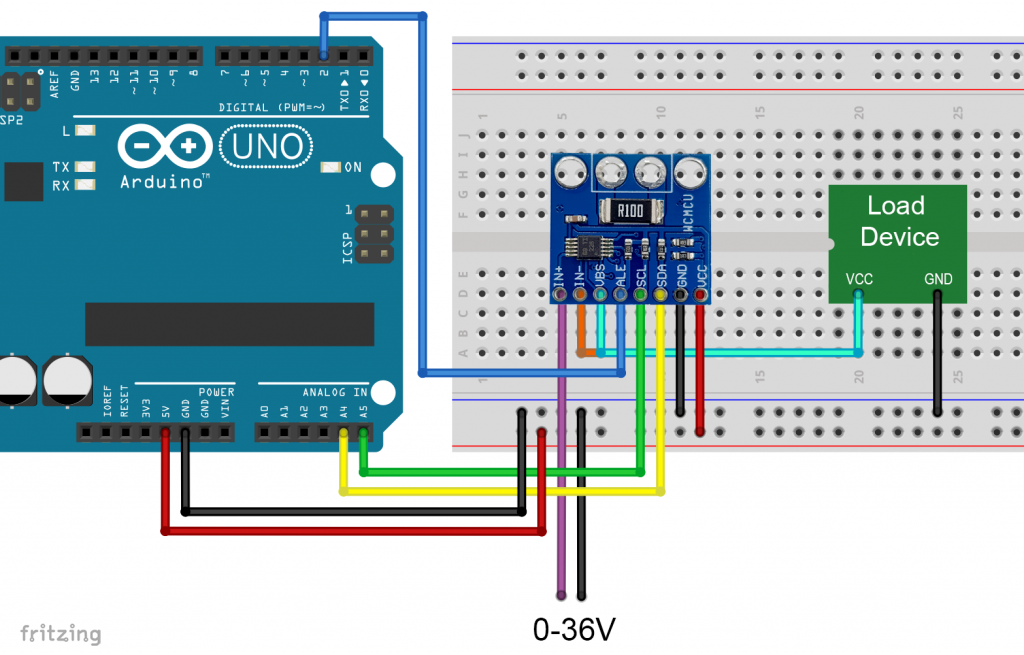

Typical circuit

I used the above (high-side) circuit for all example sketches. It is important that the INA226 and the consumer have a common GND, otherwise the measurement of the bus voltage will not work. If you swap IN+ and IN- you will get negative values for the shunt voltage and current.

Some technical data of the INA226 module

- Bus voltage: 0 – 36 volts

- Maximum bus current: 800 milliampere

- Supply voltage: 3 – 5.5 volts

- Power consumption (self-determined):

- Continuous mode: 0.35 mA

- Power-Down Mode: 2.3.µA

- Measurement modes: continuous or on-demand (“triggered”);

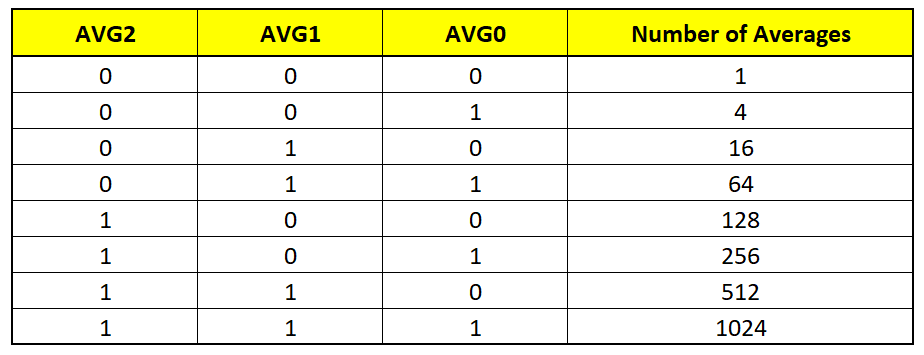

- Averaging of 1, 4, 64, 128, 256, 512 or 1024 individual measurements

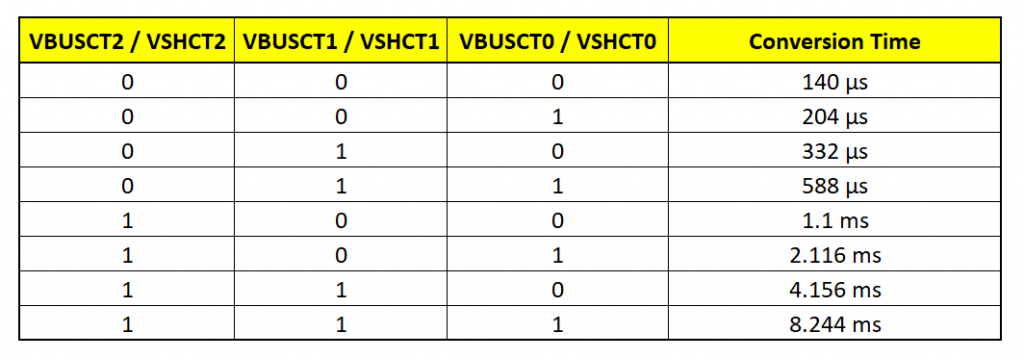

- A/D conversion time adjustable in eight levels: 0.14 to 8.2 ms

- Data registers:

- Shunt voltage register

- Bus voltage register

- Current register

- Power register

- Communication via I²C, 4 addresses can be set (back of module):

- 0x40: A0, A1 open

- 0x41: A0 closed, A1 open

- 0x44: A0 open, A1 closed

- 0x45: A0, A1 closed

- Programmable alarm pin for limit violations and available data

Further technical data can be found in the manufacturer’s data sheet.

Most INA226 modules have the 0.1 Ω shunt. However, there are also models with 0.01 or 0.02 Ω, for example. With the 0.1 Ω shunt, the maximum current is 0.819175 A. If you use the bare module, you are correspondingly more flexible. I have implemented a function that allows you to use a different resistor.

Use of the INA226 library

You can download the library INA226_WE here from GitHub or install it directly with the Library Manager of the Arduino IDE.

I have written a total of seven example sketches to demonstrate the functions of the library. I will focus most on the example of continuous mode. Many of the functions are used in all sketches and therefore only need to be explained once.

Example 1: Continuous Mode

After you have installed the library and wired your INA226, upload the sketch “Continuous.ino”.

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

Wire.begin();

if(!ina226.init()){

Serial.println("Failed to init INA226. Check your wiring.");

while(1){}

}

/* Set Number of measurements for shunt and bus voltage which shall be averaged

* Mode * * Number of samples *

INA226_AVERAGE_1 1 (default)

INA226_AVERAGE_4 4

INA226_AVERAGE_16 16

INA226_AVERAGE_64 64

INA226_AVERAGE_128 128

INA226_AVERAGE_256 256

INA226_AVERAGE_512 512

INA226_AVERAGE_1024 1024

*/

//ina226.setAverage(INA226_AVERAGE_16); // choose mode and uncomment for change of default

/* Set conversion time in microseconds

One set of shunt and bus voltage conversion will take:

number of samples to be averaged x conversion time x 2

* Mode * * conversion time *

INA226_CONV_TIME_140 140 µs

INA226_CONV_TIME_204 204 µs

INA226_CONV_TIME_332 332 µs

INA226_CONV_TIME_588 588 µs

INA226_CONV_TIME_1100 1.1 ms (default)

INA226_CONV_TIME_2116 2.116 ms

INA226_CONV_TIME_4156 4.156 ms

INA226_CONV_TIME_8244 8.244 ms

*/

//ina226.setConversionTime(INA226_CONV_TIME_1100); //choose conversion time and uncomment for change of default

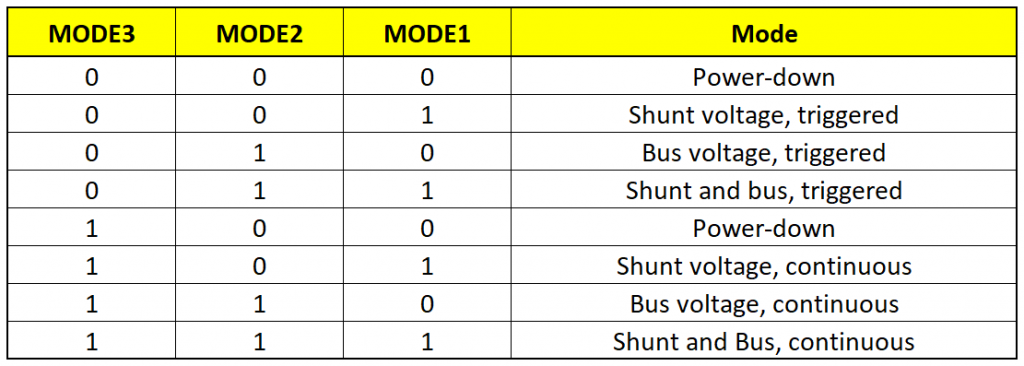

/* Set measure mode

INA226_POWER_DOWN - INA226 switched off

INA226_TRIGGERED - on demand, both current and bus voltage

INA226_TRIGGERED_CURRENT_ONLY - on demand, current only

INA226_TRIGGERERD_BUS_ONLY - on demand, bus voltage only

INA226_CONTINUOUS - continuous, both current and bus voltage (default)

INA226_CONTINUOUS_CURRENT_ONLY - continuous, current only

INA226_CONTINUOUS_BUS_ONLY - continuous, bus voltage only

*/

//ina226.setMeasureMode(INA226_CONTINUOUS); // choose mode and uncomment for change of default

/* If the current values delivered by the INA226 differ by a constant factor

from values obtained with calibrated equipment you can define a correction factor.

Correction factor = current measured with calibrated device / current measured by INA226

Be aware that Imax depends on the real shunt size.

*/

// ina226.setCorrectionFactor(0.95);

Serial.println("INA226 Current Sensor Example Sketch - Continuous");

ina226.waitUntilConversionCompleted(); //if you comment this line the first data might be zero

}

void loop() {

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

checkForI2cErrors();

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

delay(3000);

}

void checkForI2cErrors(){

byte errorCode = ina226.getI2cErrorCode();

if(errorCode){

Serial.print("I2C error: ");

Serial.println(errorCode);

switch(errorCode){

case 1:

Serial.println("Data too long to fit in transmit buffer");

break;

case 2:

Serial.println("Received NACK on transmit of address");

break;

case 3:

Serial.println("Received NACK on transmit of data");

break;

case 4:

Serial.println("Other error");

break;

case 5:

Serial.println("Timeout");

break;

default:

Serial.println("Can't identify the error");

}

if(errorCode){

while(1){}

}

}

}

Parameter setting using the example of continuous mode

INA226_WE ina226 = INA226_WE() creates your IN226 object. You can pass the I2C address and / or a wire object. The latter allows you to use both I2C buses of an ESP32, for example.

The init() function activates the INA226 with the default values. To change these basic settings, you can vary three parameters in the setup:

- Set the number of individual measurements for the shunt and bus voltage conversion with

setAverage()- 1, 4, 16, 64, 128, 256, 512 or 1024 individual measurements are averaged

- Setting the A/D conversion time for the shunt and bus voltage with

setConvTime()- 8 levels adjustable between 140 µs and 8.244 ms

- Note: obtaining a data set of shunt and bus voltage takes twice the time

- Setting the measurement mode with

setMeasureMode()- INA226_CONTINUOUS – continuous measurement (current and bus voltage, current only or bus voltage only)

- INA226_TRIGGERED – “on request” (current and bus voltage, current only, or bus voltage only)

- INA226_POWER_DOWN – switches off the INA226. But better use the more comfortable

powerDown()function, which is explained below. - The INA226 actually allows determining shunt or bus voltages – but I did not implement that. Using my library, the measurements are only available in a double pack.

With setCorrectionFactor() you can introduce a correction factor if the current values determined with the INA226 should differ from those determined by you, for example, with calibrated measuring instruments. The factor is the quotient of the exact and the INA226 value.

Other functions used in the example

You can query the data registers of the INA226 at any time. They contain the last measured value. Before the first measurement is completed, all values are zero. With waitUntilConversionCompleted() you can wait until the current measurement has been completed.

Using readAndClearFlags() the overflow and alarm flags are read. In this example sketch, we need this call only to update the state of the variable overflow, which – if true – signals the overflow of a register.

The functions for reading the data registers, such as getShuntVoltage_mV(), should be self-explanatory.

Calculation of the measurement time

The duration of a measurement results from the number of individual measurements (averages) and the conversion time. If current and bus voltage are measured, twice the time is required:

![]()

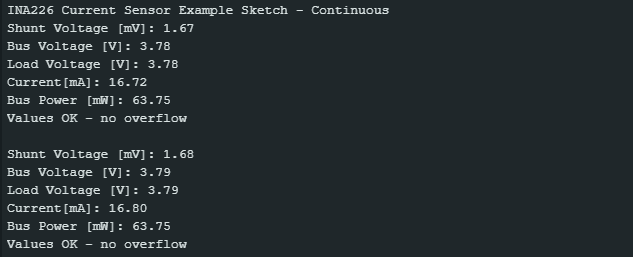

Output

And this is what the output of the sketch looks like on the serial monitor:

Example 2: On-Demand (Triggered) Mode

You set the triggered mode with setMeasureMode(TRIGGERED). Each measurement is started manually with startSingleMeasurement(). I have programmed the function to automatically wait until the current readings are available. So you don’t need to call waitUntilConversionCompleted() in triggered mode. However, this function blocks the sketch for the measurement duration. If you don’t want this, then use the startSingleMeasurementNoWait() function. You can find a sketch for this (Triggered_non_blocking.ino) in the library example sketches.

Otherwise, the sketch is identical to Continuous.ino.

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

Wire.begin();

if(!ina226.init()){

Serial.println("Failed to init INA226. Check your wiring.");

while(1){}

}

/* Set Number of measurements for shunt and bus voltage which shall be averaged

* Mode * * Number of samples *

INA226_AVERAGE_1 1 (default)

INA226_AVERAGE_4 4

INA226_AVERAGE_16 8

INA226_AVERAGE_64 64

INA226_AVERAGE_128 128

INA226_AVERAGE_256 256

INA226_AVERAGE_512 512

INA226_AVERAGE_1024 1024

*/

//ina226.setAverage(INA226_AVERAGE_1); // choose mode and uncomment for change of default

/* Set conversion time in microseconds

One set of shunt and bus voltage conversion will take:

number of samples to be averaged x conversion time x 2

* Mode * * conversion time *

INA226_CONV_TIME_140 140 µs

INA226_CONV_TIME_204 204 µs

INA226_CONV_TIME_332 332 µs

INA226_CONV_TIME_588 588 µs

INA226_CONV_TIME_1100 1.1 ms (default)

INA226_CONV_TIME_2116 2.116 ms

INA226_CONV_TIME_4156 4.156 ms

INA226_CONV_TIME_8244 8.244 ms

*/

//ina226.setConversionTime(INA226_CONV_TIME_1100); //choose conversion time and uncomment for change of default

/* Set measure mode

INA226_POWER_DOWN - INA226 switched off

INA226_TRIGGERED - on demand, both current and bus voltage

INA226_TRIGGERED_CURRENT_ONLY - on demand, current only

INA226_TRIGGERERD_BUS_ONLY - on demand, bus voltage only

INA226_CONTINUOUS - continuous, both current and bus voltage (default)

INA226_CONTINUOUS_CURRENT_ONLY - continuous, current only

INA226_CONTINUOUS_BUS_ONLY - continuous, bus voltage only

*/

ina226.setMeasureMode(INA226_TRIGGERED); // choose mode and uncomment for change of default

/* If the current values delivered by the INA226 differ by a constant factor

from values obtained with calibrated equipment you can define a correction factor.

Correction factor = current measured with calibrated device / current measured by INA226

Be aware that Imax depends on the real shunt size.

*/

// ina226.setCorrectionFactor(0.95);

Serial.println("INA226 Current Sensor Example Sketch - Triggered");

// ina226.waitUntilConversionCompleted(); //makes no sense - in triggered mode we wait anyway for comleted conversion

}

void loop() {

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

ina226.startSingleMeasurement();

ina226.readAndClearFlags();

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

checkForI2cErrors();

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

delay(3000);

}

void checkForI2cErrors(){

byte errorCode = ina226.getI2cErrorCode();

if(errorCode){

Serial.print("I2C error: ");

Serial.println(errorCode);

switch(errorCode){

case 1:

Serial.println("Data too long to fit in transmit buffer");

break;

case 2:

Serial.println("Received NACK on transmit of address");

break;

case 3:

Serial.println("Received NACK on transmit of data");

break;

case 4:

Serial.println("Other error");

break;

case 5:

Serial.println("Timeout");

break;

default:

Serial.println("Can't identify the error");

}

if(errorCode){

while(1){}

}

}

}

Example 3: Power-Down Mode

In power-down mode, you bring down the power consumption of the INA226 from approx. 0.35 mA to approx. 2.3 µA (own measurements).

The example sketch PowerDown.ino shows the power-down mode in action. The sketch initializes the INA226 with the default parameters. Five sets of measurements are output every three seconds. The function powerDown() then saves the contents of the configuration register and disables the INA226. The function powerUp() writes back the copy of the configuration register. On the one hand, this writing process awakens the INA226, on the other hand it ensures that the INA226 returns to the previously selected mode (here: continuous).

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

Wire.begin();

// default parameters are set - for change check the other examples

ina226.init();

Serial.println("INA226 Current Sensor Example Sketch - PowerDown");

Serial.println("Continuous Sampling starts");

Serial.println();

}

void loop() {

for(int i=0; i<5; i++){

continuousSampling();

delay(3000);

}

Serial.println("Power down for 10s");

ina226.powerDown();

for(int i=0; i<10; i++){

Serial.print(".");

delay(1000);

}

Serial.println("Power up!");

Serial.println("");

ina226.powerUp();

}

void continuousSampling(){

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

ina226.readAndClearFlags();

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

}

Example 4: Conversion Ready Alarm

Now upload “Continuous_Alert_Controlled.ino”. With this example, you get to know the alert pin. First, a high number of individual measurements to be averaged is set at 512. We select 8.244 milliseconds as the conversion time. This means that the combination of shunt and bus voltage measurement takes around 8.4 seconds. We select CONTINUOUS as the measurement mode. The function enableConvReadyAlert() activates the alert pin, which is active-low by default. The alert pin is connected to the Arduino Pin 2, for which we set up an interrupt.

When a measurement is finished, the alert pin goes to LOW and an interrupt is triggered. The variable “event” becomes true and the if block is processed in the main loop. First, readAndClearFlags() is executed. This will delete the conversion ready flag and also read the overflow flag. The measurement data is read and displayed. The interrupt on pin 2 was deactivated after triggering and is switched on again after the values have been output.

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

int interruptPin = 2;

volatile bool event = false;

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

pinMode(interruptPin, INPUT_PULLUP); // for modules without internal pullup

Wire.begin();

ina226.init();

/* Set Number of measurements for shunt and bus voltage which shall be averaged

* Mode * * Number of samples *

INA226_AVERAGE_1 1 (default)

INA226_AVERAGE_4 4

INA226_AVERAGE_16 16

INA226_AVERAGE_64 64

INA226_AVERAGE_128 128

INA226_AVERAGE_256 256

INA226_AVERAGE_512 512

INA226_AVERAGE_1024 1024

*/

ina226.setAverage(INA226_AVERAGE_1024);

/* Set conversion time in microseconds

One set of shunt and bus voltage conversion will take:

number of samples to be averaged x conversion time x 2

* Mode * * conversion time *

INA226_CONV_TIME_140 140 µs

INA226_CONV_TIME_204 204 µs

INA226_CONV_TIME_332 332 µs

INA226_CONV_TIME_588 588 µs

INA226_CONV_TIME_1100 1.1 ms (default)

INA226_CONV_TIME_2116 2.116 ms

INA226_CONV_TIME_4156 4.156 ms

INA226_CONV_TIME_8244 8.244 ms

*/

ina226.setConversionTime(INA226_CONV_TIME_8244); // Conversion ready after conversion time x number of averages x 2

/* Set measure mode

INA226_POWER_DOWN - INA226 switched off

INA226_TRIGGERED - on demand, both current and bus voltage

INA226_TRIGGERED_CURRENT_ONLY - on demand, current only

INA226_TRIGGERERD_BUS_ONLY - on demand, bus voltage only

INA226_CONTINUOUS - continuous, both current and bus voltage (default)

INA226_CONTINUOUS_CURRENT_ONLY - continuous, current only

INA226_CONTINUOUS_BUS_ONLY - continuous, bus voltage only

*/

//ina226.setMeasureMode(INA226_CONTINUOUS); // choose mode and uncomment for change of default

/* If the current values delivered by the INA226 differ by a constant factor

from values obtained with calibrated equipment you can define a correction factor.

Correction factor = current measured with calibrated device / current measured by INA226

Be aware that Imax depends on the real shunt size.

*/

// ina226.setCorrectionFactor(0.95);

Serial.println("INA226 Current Sensor Example Sketch - Continuous_Alert_Controlled");

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

ina226.enableConvReadyAlert(); // an interrupt will occur on interrupt pin when conversion is ready

}

void loop() {

if(event){

ina226.readAndClearFlags(); // reads interrupt and overflow flags and deletes them

displayResults();

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

event = false;

}

delay(100);

}

void displayResults(){

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

}

void alert(){

event = true;

detachInterrupt(digitalPinToInterrupt(interruptPin));

}

Practical application of the Conversion Ready Alert

During the long 8 seconds between measurements, the Arduino or the microcontroller you are using in your project has nothing to do. This consumes valuable electricity in battery-powered projects. So just send your microcontroller to sleep and let it wake up through the interrupt. If you don’t know how to do it, look here at my post on this subject.

Example 5: Limit Alert

I would like to introduce you to the Limit Alarm using the sketch Limit_Alert.ino. The INA226 runs in triggered mode. On the Arduino side, an interrupt on pin 2 is set up again.

The function enableAlertLatch() sets the alarm pin so that it is active when an alarm is raised until it is manually readAndClearFlags() set inactive again. Without this setup, the pin would be automatically reset if the next measured value is within the limits.

With setAlertType() you determine the limit and which of the measured values is observed. You can specify a min or max limit for the shunt voltage, bus voltage, or current. For the power you can only set a max limit. Actually, the INA226 has no alarm function for the current, I implemented this via a detour.

And that’s it. When the set limit is exceeded, the alarm pin becomes active, the interrupt is triggered and the measured values are read. However, the alarm is triggered for each individual measurement and not only after measurements set via averages have been completed.

You have to be a bit careful with the readAndClearFlags() function. When you read the flags to evaluate them, you delete them. If the alarm condition still exists, the alarm pin becomes active again immediately. If this happens before the interrupt is reactivated, everything gets confused. The alarm pin would already be low, while the interrupt pin would wait for a falling event. It could wait for a very long time! This is why readAndClearFlags() is called again after the interrupt has been reactivated. Separating the reading and deletion of the flags would be a little easier to control, but this is not implemented in INA226.

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

#define SAMPLING_PERIOD 500

#define OUTPUT_PERIOD 2000

int interruptPin = 2;

volatile bool limitEvent = false;

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

pinMode(interruptPin, INPUT_PULLUP); // for modules without internal pullup

Wire.begin();

ina226.init();

/* Set Number of measurements for shunt and bus voltage which shall be averaged

* Mode * * Number of samples *

INA226_AVERAGE_1 1 (default)

INA226_AVERAGE_4 4

INA226_AVERAGE_16 16

INA226_AVERAGE_64 64

INA226_AVERAGE_128 128

INA226_AVERAGE_256 256

INA226_AVERAGE_512 512

INA226_AVERAGE_1024 1024

*/

// ina226.setAverage(INA226_AVERAGE_1024);

/* Set conversion time in microseconds

One set of shunt and bus voltage conversion will take:

number of samples to be averaged x conversion time x 2

* Mode * * conversion time *

INA226_CONV_TIME_140 140 µs

INA226_CONV_TIME_204 204 µs

INA226_CONV_TIME_332 332 µs

INA226_CONV_TIME_588 588 µs

INA226_CONV_TIME_1100 1.1 ms (default)

INA226_CONV_TIME_2116 2.116 ms

INA226_CONV_TIME_4156 4.156 ms

INA226_CONV_TIME_8244 8.244 ms

*/

// ina226.setConversionTime(INA226_CONV_TIME_8244);

/* Set measure mode

INA226_POWER_DOWN - INA226 switched off

INA226_TRIGGERED - on demand, both current and bus voltage

INA226_TRIGGERED_CURRENT_ONLY - on demand, current only

INA226_TRIGGERERD_BUS_ONLY - on demand, bus voltage only

INA226_CONTINUOUS - continuous, both current and bus voltage (default)

INA226_CONTINUOUS_CURRENT_ONLY - continuous, current only

INA226_CONTINUOUS_BUS_ONLY - continuous, bus voltage only

*/

ina226.setMeasureMode(INA226_TRIGGERED); // choose mode and uncomment for change of default

/* If the current values delivered by the INA226 differ by a constant factor

from values obtained with calibrated equipment you can define a correction factor.

Correction factor = current measured with calibrated device / current measured by INA226

Be aware that Imax depends on the real shunt size.

*/

// ina226.setCorrectionFactor(0.95);

Serial.println("INA226 Current Sensor Example Sketch - Limit_Alert");

/* In the default mode the limit interrupt flag will be deleted after the next measurement within limits.

With enableAltertLatch(), the flag will have to be deleted with readAndClearFlags().

*/

ina226.enableAlertLatch();

/* Set the alert type and the limit

* Mode * * Description * * limit unit *

INA226_SHUNT_OVER Shunt Voltage over limit mV

INA226_SHUNT_UNDER Shunt Voltage under limit mV

INA226_CURRENT_OVER Current over limit mA

INA226_CURRENT_UNDER Current under limit mA

INA226_BUS_OVER Bus Voltage over limit V

INA226_BUS_UNDER Bus Voltage under limit V

INA226_POWER_OVER Power over limit mW

*/

ina226.setAlertType(INA226_POWER_OVER, 250.0); // alert, if power > 250.0 mW

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

}

void loop() {

static unsigned long lastMeasurement = 0;

static unsigned long lastOutput = 0;

if(millis() - lastMeasurement >= SAMPLING_PERIOD) {

ina226.startSingleMeasurementNoWait();

lastMeasurement = millis();

}

if(millis() - lastOutput >= OUTPUT_PERIOD) {

lastOutput = millis();

displayResults();

}

if(limitEvent){

ina226.readAndClearFlags(); // reads interrupt and overflow flags and deletes them

Serial.println("ALERT!");

displayResults();

lastOutput = millis();

limitEvent = false;

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

ina226.readAndClearFlags();

}

}

void displayResults(){

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

}

void alert(){

limitEvent = true;

detachInterrupt(digitalPinToInterrupt(interruptPin));

}

Example 6: Limit and Conversion Alert

I hope you are still motivated – that is the last example. With the sketch Limit_And_Conversion_Alert.ino I want to show how you can use the limit and the conversion ready alarm side by side. Both alarms are activated as in the previous sketches.

In the event of an alarm, you now want to be able to distinguish which condition triggered the alarm. In case of alarm, read the flags via readAndClearFlags() . This will update the variables limitAlert and convAltert and allow you to query them.

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

int interruptPin = 2;

volatile bool event = false;

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

pinMode(interruptPin, INPUT_PULLUP); // for modules without internal pullup

Wire.begin();

ina226.init();

// Conversion will be ready after conversion time x number of averages x 2

ina226.setAverage(INA226_AVERAGE_512);

ina226.setConversionTime(INA226_CONV_TIME_8244);

// ina226.setCorrectionFactor(0.95);

Serial.println("INA226 Current Sensor Example Sketch - Limit_And_Conversion_Alert");

/* In the default mode the limit interrupt flag will be deleted after the next measurement within limits.

With enableAltertLatch(), the flag will have to be deleted with readAndClearFlags().

*/

ina226.enableAlertLatch();

/* Set the alert type and the limit

* Mode * * Description * * limit unit *

INA226_SHUNT_OVER Shunt Voltage over limit mV

INA226_SHUNT_UNDER Shunt Voltage under limit mV

INA226_CURRENT_OVER Current over limit mA

INA226_CURRENT_UNDER Current under limit mA

INA226_BUS_OVER Bus Voltage over limit V

INA226_BUS_UNDER Bus Voltage under limit V

INA226_POWER_OVER Power over limit mW

*/

ina226.setAlertType(INA226_CURRENT_UNDER, 3.0); // alert, if current is below 3.0 mA

ina226.enableConvReadyAlert(); // In this example we also enable the conversion ready alert interrupt

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

}

void loop() {

static unsigned long lastLimitAlert = 0;

if(event){

ina226.readAndClearFlags();

if(ina226.convAlert){

Serial.println("Conversion Alert!!!!");

displayResults();

}

/*

The limit alert is fired after every single measurement. I does not

wait until the averaged value is ready. Therefore, I reduce the number

of outputs.

*/

if(ina226.limitAlert){

if (millis() - lastLimitAlert >= 1000) {

Serial.println("Limit Alert !!!!");

lastLimitAlert = millis();

}

}

event = false;

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

ina226.readAndClearFlags();

}

}

void displayResults(){

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

}

void alert(){

event = true;

detachInterrupt(digitalPinToInterrupt(interruptPin));

}

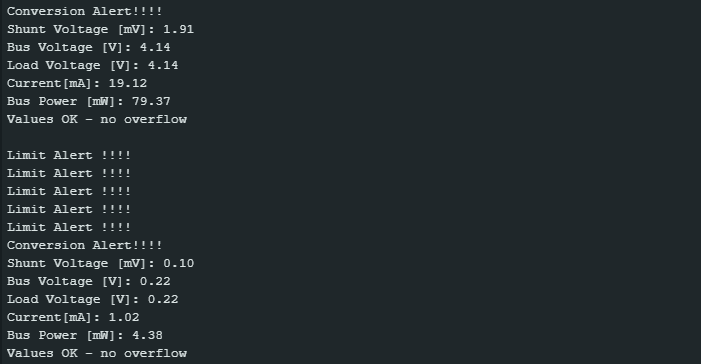

Output of Limit_And_Conversion_Alert.ino

For the following output, I waited for a regular output within the limits and then switched off my load. As a result, the set limit is permanently exceeded. Accordingly, the sketch outputs limit violations every second. Under the conditions set above, the sketch also issues a conversion ready alert approx. every 8 seconds:

Example 7: Continuous with alternative shunt size

A diligent contributor has added another feature to my library that allows you to use alternative shunts:

setResistorRange(0.005, 10.0)sets the resistance in ohms and the range in amperes. The maximum current Imax [A] = 0.0819175 / shuntSize (with shuntSize in Ohm) is the upper limit.setResistorRange(0.005)specifies the resistance, and the maximum range is calculated from this: Imax [A] = 0.0819175 / shuntSize with shuntSize in ohms.

The sketch works like the Continuous.ino sketch, but with the additional function. You can find it in the example sketches provided.

But aware: many INA226 modules with smaller shunts are scrap! I have written something about this here on Github.

#include <Wire.h>

#include <INA226_WE.h>

#define I2C_ADDRESS 0x40

/* There are several ways to create your INA226 object:

* INA226_WE ina226 = INA226_WE(); -> uses I2C Address = 0x40 / Wire

* INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

* INA226_WE ina226 = INA226_WE(&Wire); -> uses I2C_ADDRESS = 0x40, pass any Wire Object

* INA226_WE ina226 = INA226_WE(&Wire, I2C_ADDRESS);

*/

INA226_WE ina226 = INA226_WE(I2C_ADDRESS);

void setup() {

Serial.begin(115200);

while(!Serial); // wait until serial comes up on Arduino Leonardo or MKR WiFi 1010

Wire.begin();

ina226.init();

/* Set Number of measurements for shunt and bus voltage which shall be averaged

* Mode * * Number of samples *

INA226_AVERAGE_1 1 (default)

INA226_AVERAGE_4 4

INA226_AVERAGE_16 16

INA226_AVERAGE_64 64

INA226_AVERAGE_128 128

INA226_AVERAGE_256 256

INA226_AVERAGE_512 512

INA226_AVERAGE_1024 1024

*/

//ina226.setAverage(INA226_AVERAGE_16); // choose mode and uncomment for change of default

/* Set conversion time in microseconds

One set of shunt and bus voltage conversion will take:

number of samples to be averaged x conversion time x 2

* Mode * * conversion time *

INA226_CONV_TIME_140 140 µs

INA226_CONV_TIME_204 204 µs

INA226_CONV_TIME_332 332 µs

INA226_CONV_TIME_588 588 µs

INA226_CONV_TIME_1100 1.1 ms (default)

INA226_CONV_TIME_2116 2.116 ms

INA226_CONV_TIME_4156 4.156 ms

INA226_CONV_TIME_8244 8.244 ms

*/

//ina226.setConversionTime(INA226_CONV_TIME_1100); //choose conversion time and uncomment for change of default

/* Set measure mode

INA226_POWER_DOWN - INA226 switched off

INA226_TRIGGERED - on demand, both current and bus voltage

INA226_TRIGGERED_CURRENT_ONLY - on demand, current only

INA226_TRIGGERERD_BUS_ONLY - on demand, bus voltage only

INA226_CONTINUOUS - continuous, both current and bus voltage (default)

INA226_CONTINUOUS_CURRENT_ONLY - continuous, current only

INA226_CONTINUOUS_BUS_ONLY - continuous, bus voltage only

*/

//ina226.setMeasureMode(INA226_CONTINUOUS); // choose mode and uncomment for change of default

/* Set Resistor and Current Range

Most INA226 modules use a 0.1 ohms shunt. If you have a board with a different shunt you need

to set it with setResistorRange(). You pass the shunt value in ohms. The maximum current you

can measure is Imax [A] = 0.0819175 / shuntSize.

If you only expect currents lower than this Imax, you can also pass the expected Imax as a

second parameter. The resolution is determined by the shunt register LSB (2.5 µV). However,

passing a smaller Imax may result in a little higher resolution when the current is calculated.

*/

//ina226.setResistorRange(0.005,10.0); // Example: shunt is 5 mOhm and expected Imax is 10 A

ina226.setResistorRange(0.005); // Shunt is 5 mOhm, Imax is 16.3835 by default

/* If the current values delivered by the INA226 differ by a constant factor

from values obtained with calibrated equipment you can define a correction factor.

Correction factor = current measured with calibrated device / current measured by INA226

Be aware that Imax depends on the real shunt size.

*/

// ina226.setCorrectionFactor(0.95);

Serial.println("INA226 Current Sensor Example Sketch - Continuous");

ina226.waitUntilConversionCompleted(); //if you comment this line the first data might be zero

}

void loop() {

float shuntVoltage_mV = 0.0;

float loadVoltage_V = 0.0;

float busVoltage_V = 0.0;

float current_mA = 0.0;

float power_mW = 0.0;

ina226.readAndClearFlags();

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

current_mA = ina226.getCurrent_mA();

power_mW = ina226.getBusPower();

loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000);

Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV);

Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V);

Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V);

Serial.print("Current[mA]: "); Serial.println(current_mA);

Serial.print("Bus Power [mW]: "); Serial.println(power_mW);

if(!ina226.overflow){

Serial.println("Values OK - no overflow");

}

else{

Serial.println("Overflow! Choose higher current range");

}

Serial.println();

delay(3000);

}

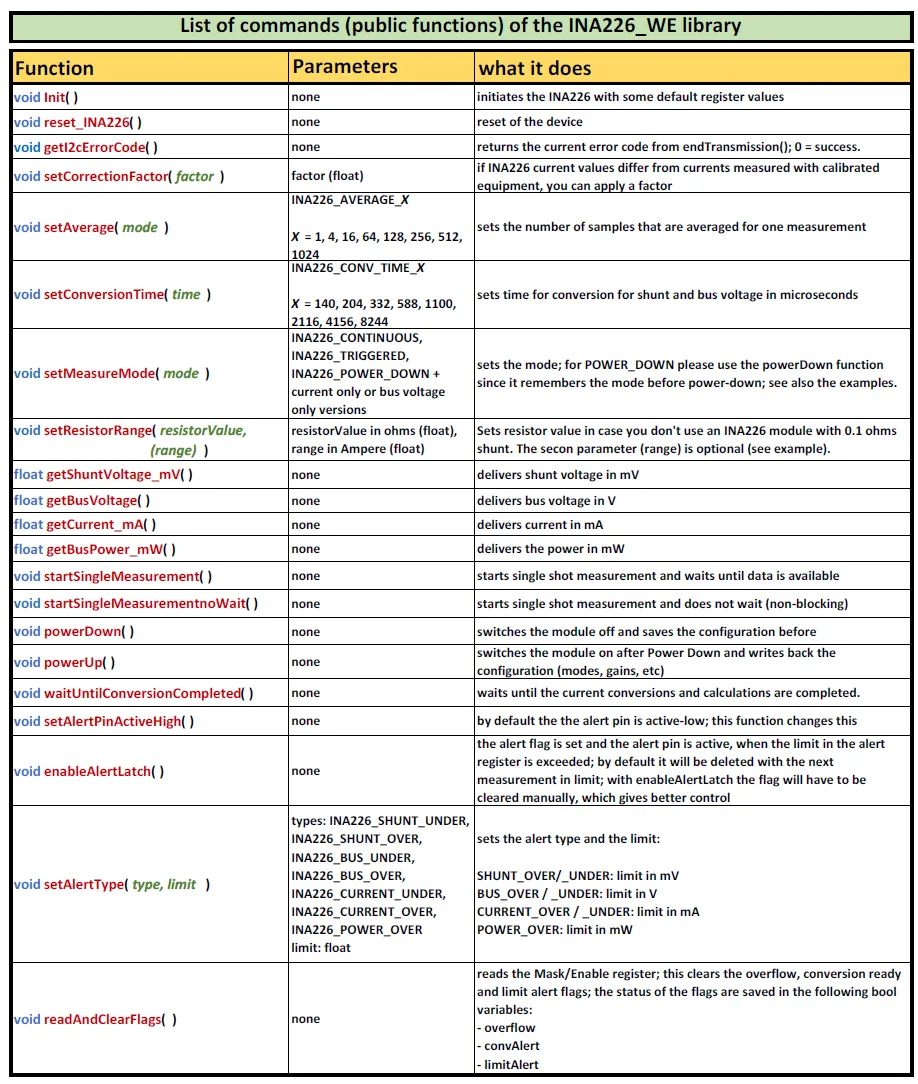

All functions at a glance

Here you can see all the functions at a glance. I also use the table for documentation on GitHub.

Details of the library and the registers of the INA226

If you still want to know more, you can now go a little deeper into the INA226 and the library.

The registers of the INA226

The INA226 has 10 registers, which is significantly more than the INA219 with its 6 registers. All registers are 16 bits.

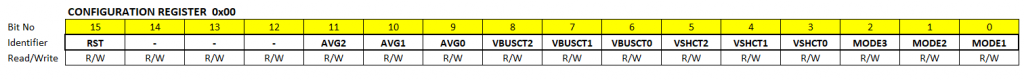

Configuration Register

In the configuration register you can make basic settings:

- RST – Reset Bit: if it is set, a reset is triggered.

- AVGX – Average Bits: determine the number of individual measurements to be averaged.

- VBUSCTX – Bus Voltage Conversion Time Bits: see table.

- VSHCTX – Shunt Voltage Conversion Time Bits: see table.

- I have made the simplification that only one conversion time can be selected, it then applies equally to the conversion of the bus and the shunt voltage.

- MODEX – MODE Bits: set the mode, see table.

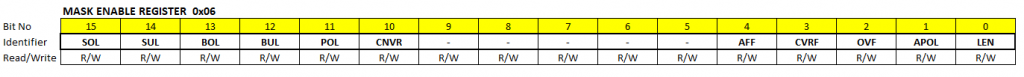

Mask/Enable Register

I jump to the Mask/Enable Register because this is the other register for settings.

Bits 10 to 15 are used to activate the alarms:

- SOL / SUL: Shunt Voltage Over / Under Limit Alert

- BOL / BUL: Bus Voltage Over / Under Limit Alert

- POL: Power Over Limit Alert

- CNVR: Conversion Ready Alert

You can only activate one of the limit alerts. If you set several bits, then the highest applies. You can only activate the Conversion Ready Alarm in parallel.

In my library I have implemented an additional Current Over and Current Under Alarm. Internally, the SOL or SUL bit is set and the current limit is converted into a shunt voltage limit.

Further settings can be made with the APOL and the LEN bit:

- APOL: Alert Pin Polarity Bit – polarity of the alarm pin. Default is active-high (APOL = 0).

- LEN: Latch Enable Bit. By default, Latch is disabled (LEN = 0). This means that the alarm pin is deactivated and the alarm flag bit is deleted as soon as an OK measurement occurs (no limit exceeded). If LEN is set, the alarm pin remains activated and the alarm flag bit is set until the Mask/Enable register is read (

readAndClearFlags()).

The INA226 sets three flags, depending on the setting and measurement results:

- AFF: Alarm Function Flag – a limit has been exceeded.

- CVRF: Conversion Ready Flag – measurement results are available.

- OVF: Overflow Flag – a data register has overflowed.

The CVRF bit is deleted when the Mask/Enable Register is read or Configuration Register is described.

I programmed the function readAndClearFlags() to store the state of AFF, CVRF and OVF in the limitAlert, convAlert, and overflow variables.

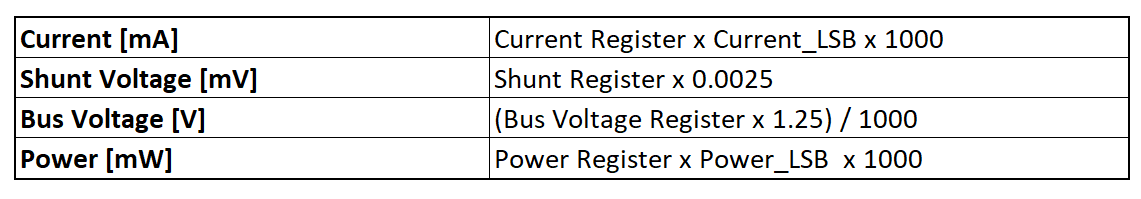

Shunt Voltage Register

The Shunt Voltage Register contains the shunt voltage with an LSB (least significant bit) of 2.5 µV. In other words, the resolution of the shunt register is 2.5 µV per unit. Because the register has a sign bit, the value range of the shunt voltage is limited to:

![]()

By modifying the shunt you could theoretically change the maximum measurable current. However, you have no choice with the module, and you have to live with the 0.1 ohms. This results in a measuring range of +/- 819,175 mA for the current. In the case of INA219, on the other hand, the current LSB is 10 V. This means that the maximum measurable current is four times larger, but with a lower resolution.

Bus Voltage Register

The INA226 saves the result of the bus voltage conversion to the Bus Voltage Register. Only 15 bits are used by the Bus Voltage Register – the sign is always positive. The LSB is 1.25 mV, resulting in a maximum bus voltage of 40.96 V.

Current Register

The INA226 stores the current calculated from the shunt voltage in the Current Register. This is where things get a little complicated, as a calibration factor CAL comes into play, which depends on the maximum expected current and the size of the shunt:

![]()

![]()

When calculating the calibration value, you start with the maximum expected current. For my library, I have selected 0.8192 amperes as the maximum. The formula for CAL would give an uncomfortable value for 0.819175, so I rounded up a little. The content of the Current Register is as follows:

![]()

In the end, you need to multiply the content of the Current Register by the Current_LSB to get the current.

The library automatically calculates the calibration factor for other shunt sizes.

Power Register

The Power Register contains the calculated power according to the following formula:

![]()

Finally, the power is the content of the Power Register, multiplied by the Power_LSB. The Power_LSB is (internally defined):

![]()

Calibration Register

The Calibration Register contains the above-mentioned calibration value.

Alert Limit Register

You enter the alarm limit in the Alert Limit Register. I have implemented this in such a way that you can pass the limits directly via the function setAlertType() in the respective designated units.

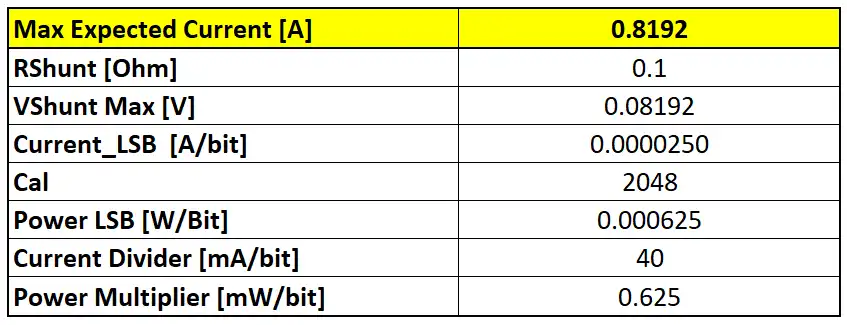

Calculation of calibration factors and LSBs

The library converts the content of the data registers into the desired units with the LSBs and other factors:

To get handy convenient factors, I introduced a Current Divider and a Power Multiplier:

![]()

![]()

and

![]()

![]()

I implemented the following values in the library:

Acknowledgement

The picture of the current meter is from the Free-Photos of Pixabay. I also found the alarm light from Alexey Hulsov and the display from the OpenClipart vectors on Pixabay.

Hello.

I connected the INA226 module to the ESP32. The resistance of the shunt used is 0.01 ohms.

When measuring, I constantly get the “Overload” event. I don’t understand what the problem is.

Can you tell me?

Initialization code:

void INA_Init()

{

ina226.init();

ina226.setAverage(AVERAGE_128);

ina226.setConversionTime(CONV_TIME_2116);

ina226.setResistorRange(0.01,7.0);

ina226.setCorrectionFactor(0.985);

ina226.waitUntilConversionCompleted();

}

Measurement code:

void Meashure()

{

ina226.readAndClearFlags();

if(ina226.overflow){Serial.print(“Overflow! Choose higher current range. I=”);Serial.println(ina226.getCurrent_mA());}

shuntVoltage_mV = ina226.getShuntVoltage_mV();

busVoltage_V = ina226.getBusVoltage_V();

Voltage = busVoltage_V + (shuntVoltage_mV/1000);

Current = ina226.getCurrent_mA();

}

The measurement process is performed by core No. 0

void Task0Code( void * parameter )

{

for (;;)

{

if (millis() – LastMeashure >= 100)

{

Meashure();

LastMeashure = millis();

}

vTaskDelay(10);

}

}

A warning in the port monitor:

Overflow! Choose higher current range. I=1358.86

Overflow! Choose higher current range. I=354.19

Overflow! Choose higher current range. I=2792.27

Overflow! Choose higher current range. I=1764.74

Overflow! Choose higher current range. I=751.53

Overflow! Choose higher current range. I=-374.27

Overflow! Choose higher current range. I=-374.27

Overflow! Choose higher current range. I=3141.11

Hi, I have tried to reproduce your settings and apply simple code. I also connected a module with an 0.01 ohms resistor (R010). This is the sketch I have uploaded to my ESP32:

#include <Wire.h> #include <INA226_WE.h> #define I2C_ADDRESS 0x40 INA226_WE ina226 = INA226_WE(I2C_ADDRESS); void setup() { Serial.begin(115200); while(!Serial); // wait until serial comes up on Arduino Leonardo or MKR WiFi 1010 Wire.begin(); ina226.init(); ina226.setAverage(INA226_AVERAGE_128); // choose mode and uncomment for change of default ina226.setConversionTime(INA226_CONV_TIME_2116); //choose conversion time and uncomment for change of default ina226.setMeasureMode(INA226_CONTINUOUS); // choose mode and uncomment for change of default ina226.setResistorRange(0.01, 7.0); ina226.setCorrectionFactor(1.0); ina226.waitUntilConversionCompleted(); //if you comment this line the first data might be zero } void loop() { float shuntVoltage_mV = 0.0; float loadVoltage_V = 0.0; float busVoltage_V = 0.0; float current_mA = 0.0; float power_mW = 0.0; ina226.readAndClearFlags(); shuntVoltage_mV = ina226.getShuntVoltage_mV(); busVoltage_V = ina226.getBusVoltage_V(); current_mA = ina226.getCurrent_mA(); power_mW = ina226.getBusPower(); loadVoltage_V = busVoltage_V + (shuntVoltage_mV/1000); Serial.print("Shunt Voltage [mV]: "); Serial.println(shuntVoltage_mV); Serial.print("Bus Voltage [V]: "); Serial.println(busVoltage_V); Serial.print("Load Voltage [V]: "); Serial.println(loadVoltage_V); Serial.print("Current[mA]: "); Serial.println(current_mA); Serial.print("Bus Power [mW]: "); Serial.println(power_mW); if(!ina226.overflow){ Serial.println("Values OK - no overflow"); } else{ Serial.println("Overflow! Choose higher current range"); } Serial.println(); delay(1000); }The code works without issues. I don’t get overflows. Can you try exactly the same code?

And what kind of module do you use? If you have one of the red ones I have described here:

https://github.com/wollewald/INA226_WE?tab=readme-ov-file#quality-of-small-shunt-ina226-modules

then you need to apply the current to the big connectors.

What current values are you measuring? At what voltage?

I just applied the 3.3 volts and a small load of around 50 mA. What have you applied? The output you shared seem to be random numbers. Or is it AC? Do you have a stable DC load with known current consumption you can test?

These are the values of the cyclic charge -discharge current of the battery at a voltage of 14.6 V

I have tried ~1 A / 5 V and it works fine for me. So not sure what’s wrong at your end. If you think the issue is related to my library, then I suggest trying another one. There are several available. Not all allow setting a different shunt, but this is no problem. Just multiply the current accordingly.

And you could still try the sketch I have shown in my first reply. A few days ago I had published an update (1.4.0) of my library (which should have no effect on the issue you face). I have updated the sketch above so that it works with the new version.

Thank you for your answers.

I’ll try your sketch and the new version of the library. But I think the problem lies in the module itself.

Hi Wolfgang, firstly thank you for providing your INA226 library. For my application, I do not need to measure bus voltage, so I want to set the measurement mode to continuous shunt voltage only (101). Is there any way that I can implement this? Will simply adding the mode into the INA226_MEASURE_MODE enum work? Thank you

Hi Albert,

I can implement this, but it will take time. In the meantime you can modify my library. It is the enum INA226_MEASURE_MODE. The first bit (counting from right to left) is for the shunt measurement (1=active), the second is for bus measurement (1=active), and the third bit is for continous vs. single shot (1=continuous).

So as you rightly say 101 would be the correct setting. So just go into the cpp file, line 57 and 61, and change 0b00000111 to 0b00000101. That should be the easiest way. Or you try and extend the enum. It should also work. I put this on my to-do list, but it is quite long.

I’ve added an entry into the enum and it seems to work (bus voltage reading became 0). I appreciate your detailed response and confirmation. Cheers!

I used the exaxtly same circuit diagram in this page.My Vbus is 5V and i used series of different resistor for a load.Then I opened Continuous_With_Resistor_Value.ino example and upload it to Nano as it is without any minor changes.My shunt resistor is 5miliOhm.(0.005)

Load : 216 Ohm

Multimeter Value [mA]: 22.44

18:56:30.441 -> Shunt Voltage [mV]: 0.64

18:56:30.441 -> Bus Voltage [V]: 4.85

18:56:30.486 -> Load Voltage [V]: 4.85

18:56:30.486 -> Current[mA]: 127.56

18:56:30.486 -> Bus Power [mW]: 610.35

18:56:30.486 -> Values OK – no overflow

————————————————-

Load : 385 Ohm

Multimeter Value [mA]: 12.80

19:06:01.107 -> Shunt Voltage [mV]: 0.35

19:06:01.107 -> Bus Voltage [V]: 4.92

19:06:01.140 -> Load Voltage [V]: 4.92

19:06:01.140 -> Current[mA]: 71.11

19:06:01.140 -> Bus Power [mW]: 350.95

19:06:01.140 -> Values OK – no overflow

————————————————

Load : 4,62 KOhm

Multimeter Value [mA]: 1.09

19:09:34.760 -> Shunt Voltage [mV]: 0.03

19:09:34.760 -> Bus Voltage [V]: 5.02

19:09:34.794 -> Load Voltage [V]: 5.02

19:09:34.794 -> Current[mA]: 5.49

19:09:34.794 -> Bus Power [mW]: 22.89

19:09:34.794 -> Values OK – no overflow

And what have you chosen as maximum expected current?

ina226.setResistorRange(0.005,?????);

As i said mate I didn’t touch it : ( ina226.setResistorRange(0.005,10.0); )

I replaced the shunt with a different 3W smd one.Its resistance can be read on as R005 and nothing changed.Then again i did replaced it with wire type shunt resistor which i had previous known to be the 10miliOhm this time.Accuracy improved this time but it still had like 50 error margin.Thank you for giving your time.Much appriciated

Your multimeter values seem to be correct and the INA226 are 5 – 5.5 times too high. I have just tested a module with an R002 shunt and it works fine with the Continuous_With_Resistor_Value.ino sketch. Therefore, I can say that there is no issue with the library. It seems like the shunt is smaller than 5 milliohms. Maybe you can double-check. The other way round would be easier to explain, e.g. by additional resistance because of bad contacts. No idea why the shunt could differ so much.

I am writing this just to let you know that all the modules in my possessions turned out to be counterfeit.Thank you indeed for quick responces.Cheers

Thanks for letting me know. I am happy to hear you found the problem, but how disappointing for you to spend so much time! Can you share how you found out? Could be useful for other readers who experience similar issues. All these counterfeits are really annoying.

Hi,

Thank you for the work you put in this library.I have a problem with measurement of ampere.I changed the shunt resistor with a value of 5miliOhmon my module.Then I opened Continuous_With_Resistor_Value.ino example and made necessary changes.Even so I can’t get a correct reading of ampere.My serial connected multimeter shows 20 miliamp but I get 123 miliamp with the module.I am stuck at this point.

Any help is much appriciated.

Hi, is this deviation linear? I.e. if you measure 40 milliamps (according to your multimeter), do you then measure something in the range of 246 milliamps with the module (a constant factor)? Or 143 milliamps (parallel shift)?

It may help to understand the reason if you vary the current, and could share the results you measure with the module and with your multimeter. Also, the values without any current would be helpful.

And which expected current did you choose?

Thanks for such an extensive example for the INA226.

I have loaded the Continuous sketch and uploaded it to an esp32. however, when I open the serial monitor i don’t get any feedback. The screen is blank, no error messages no read outs from the chip.

any ideas what could be causing the program to lockup.

Maybe wrong baud rate? Or the INA226 is not connected and the message “Failed to init INA226. Check your wiring.” is not displayed because it takes time until Serial is set up. You should see it if you reset the ESP32 or if you add a delay(2000) at the begin of setup(). Then we would have to answer the question of why it is not connected. But one step after the other.

Hello.

I tryed to check the current from 200 uA to 400mA, change shunt resistor (0.1 ~0.39 ohm)

( Test Supply Voltage : 11 ~ 14 Volt)

I have a questions about Shunt Voltage is required minunum value?

If I want to check 200uA of Current, Which shunt resistor value I have to condier?

Please give me a advice .

Thanks. in advance.

Hi, the shunt voltage register has a range from -81.920 to +81.9175 mV. The resolution is 2.5 µV. The maximum voltage you are going to measure limits the maximum shunt size. To use the full resolution at 400 mA, the shunt size would be R = U_max/I = 0.0819175 / 0.4 = ~0.2048… ohms. With this, your resolution for the current would be 0.4 A / (2^15-1) = ~12.2 µA. So, if you got a result of 200 µA, it would be in fact 200 µA +/-12.2 µA.

But this is the ideal, purely calculatory view. In reality, you might have some noise, and there might be unwanted resistances in your circuit, in particular if you try things on a breadboard. To reduce noise, you should use a stable power supply, solder contacts, choose a long conversion time and average many results.

I’m trying to use this library with Raspberry pi pico. The problem is that initialization fails. I found if after I saw that Init() function returns Boolean value. Now I guess that the I2C port may be incorrect. How can I check or set the I2C port?

You can use an I2C scanner sketch to check which I2C addresses are available:

https://wolles-elektronikkiste.de/en/i2c-scanner?lang=en

If none is available, then check your wiring and maybe try adding pullup resistors to the I2C lines.

I haven’t read through all the earlier comment – sorry. But I can’t see what the ‘Range’ parameter does in the ‘setresistorrange()’ function.

In the library header file I can’t find the function.

If we define the resistor, the current is defined by the shunt voltage so I’m at a loss.

What am I missing here.

Thanks

The maximum current you can measure is indeed limited by the shunt size:

maxCurrent = 81.9175 mV / shuntSize.

Since the LSB of the current register is:

currentLSB = maxExpectedCurrent/2^15

…there is a higher resolution if you choose a maximum current lower than the theoretical maximum current. But to be honest, this is just calculatory resolution. In the end it’s the resolution of the shunt register and the shunt size which limits the resolution.

Hello Wolfgang, guten Tag Herr Ewald,

Thank you for your work on the libraries!!!

I have a question about the INA219 and INA226. I have tried them both with your libraries and with two different ESP32-S3 LCD/touchscreen boards. The Waveshare 4.3″ and the WT32-SC01 plus.

On the first board I have a full i2c bus, on the second only the INA (0x40).

On both setups I use LVGL. On the WT32-SC01 plus combined with LovyanGFX.

Now what happens is this: only when I completely comment out the graphics part I get readings from the INA’s. As soon as I want to use graphics, all readings are zero. It looks like the LVGL is the reason for this. Did you encounter this at any point and/or am I doing something stupid??

Any help or hint is highly appreciated…

(I tried to add some code but got a spam message for some reason.)

Update:

Indeed, I was stupid. I just realised that there is a different i2c bus for the touchscreen!! That bus took over and the INA’s got put out of business.

I created a Wire1 with the extended IO and the problems are solved!!

Thanks anyway!!

Hi Ewald,

Thanks for this great article!

I would like to measure the current of a system, no need for the power.

Is it correct to connect the system GND to IN- , and system positive side to VBS pin?

Then I though to monitor voltage with “busVoltage_V = ina226.getBusVoltage_V();”.

Is it a requirement to have a common ground between ESP8266 side, and the system GND?

To provide additional background, I have an doorbell, connected to a inter-phone. The doorbell receive 5.2V when idle, and 18V when active. So I would like to monitor voltage, and send notification to my phone when someone press the doorbell.

Hi Adrien, your bus circuit and the INA226 need to have the same GND, otherwise the INA226 would not be able to determine the bus voltage. The reference is the GND of the INA226. So, if the bus GND and the INA226 GND would be different, the measured values would be meaningless. And your microcontroller and the INA226 need have the same GND because it is the reference for the I2C communication.

IN- shall only be connected to GND if you choose the low side configuration, i.e. the load is on the positive power supply side and the INA 226 is on the GND side: V+ – Load+ – Load- – In+ – IN+ – GND. In that case you would connect VBUS to V+.

Hope this helps!

Regards, Wolfgang

Thank you for clarification. Sorry, I’m new to this topic, so just to be sure, let’s assume I want to monitor the voltage of a 3.7V battery, without any actual load, just the battery.

Should I connect

INA226 IN- —–> Battery Negative

INA226 IN+ —–> Battery Positive

or can I use following

INA226 IN- —–> Battery Negative

INA226 VBUS —–> Battery Positive

and monitor with ina226.getBusVoltage_V() ?

By the way, on ESP8266 INA226 side, I have

GPIO4 (SDA) —-> SDA

GPIO5 (SCL) —-> SCL

GND —-> GND

3.3V —-> VCC

Maybe you have not yet understood what the INA226 does. It is primarily a current sensor. The current flows through IN+ to IN-

Between IN+ and IN- there is a resistor (shunt). The voltage dop is measured and from that the INA226 calculates the current. This has nothing to do with the voltage of your battery. However, in addition to that feature the INA226 is able to measure the bus voltage in order to calculate the power from that (current x voltage). If you only want to use this feature then just connect GND to battery minus and VBUS to battery plus. But in this case I would not use an INA226 but a simple A/D converter like the ADS1115.

Regards, Wolfgang

What about measuring current of a square signal (+30 -30 volt) with this sensor, which is applied to a 2k load? how can I handle this?

IN+ and IN- can have a negative differential voltage, but both IN+ and IN- shall not be connected to a voltage of smaller than -0.3V vs. GND. Therefore, there is no easy solution to your problem.

Hi.

You have an error in your code: you enable interrupt 0 and disable interrupt 2.

…

attachInterrupt(digitalPinToInterrupt(interruptPin), alert, FALLING);

…

void alert(){

event = true;

detachInterrupt(2);

}

Oops, yes, forgot the digitalPinToInterrup(interruptPin) in the detachInterrupt() functions – thanks!

Hi,

First of, thank you so much for this library !

I am using a INA226 module from aliexpress with a R010 (0.01 ohm) shunt resistor (rated 20A, but I only need to measure up to 6A).

My goal is to measure a 12V brushed DC motor current consumption in order to determine the resistance of its load.

I setup the resistor with

ina226.setResistorRange(0.01, 10.0);

which seems to be working fine as the measurments without load on the motor are close to what the lab power supply and a DMM in series show.

My problem is that once I apply some resistance on the output of the motor, the current increases, and once it reaches ~500mA (sometimes 800mA depending on the conversion time/average), the getCurrent_mA only returns 0 (same for power), even after the load is back to nominal (~230mA). It works again after resetting the esp32

What I noticed in my tests is that the conv alert is usually oscillating between 0 and 1 before the getCurrent_mA stops working, and stays at 1 afterwards.

On the other hand, the shunt voltage seems to keep reporting a value, but when plotting the shunt voltage value, it seems that before the error, it is quite smooth (with the average), and after the error, it is very irregular.

I am not sure whether this could be related to the lib or a faulty module, or maybe a mistunderstanding on my side.

Any input would be welcome

Hi,

not sure what the reason could be. I have not seen this issue before. I doubt that you have a faulty module because then I would expect problems not only above a certain current limit. Do you use the sketch “Continuous_With_Resistor_Value.ino”? Did you apply any changes apart from the setting of the resistor and range? If yes, can you send me the code (wolfgang.ewald@wolles-elektronikkiste.de).

To check whether your module works you could try an alternative library: https://github.com/Zanduino/INA, example sketch DisplayReadings.ino.

And which microcontroller board are you using?

Regards, Wolfgang

Thank you for your reply,

It was based on the continuous_with_resistor_value with a few tweaks,

but I tried with Zanduino/INA just now and I can see the exact same behavior.

So the issue is definitely not in the library

I am using an ESP32 devkit (With CH340C/USBC) from aliexpress, powered via USB and powering the INA module from the 3.3V output.

Here is an image with plots showing what happens :

https://imgur.com/a/COjCNj9

I will order a different INA module to see if it behaves differently. In the mean time, I am using the shunt voltage divided by the resistance, which is good enough I guess

Regards,

Julien

Hi Julien,

this is weird! In particular, I don’t understand that you still measure “something” as shunt voltage, but 0 as current. Since the current is just calculated by the INA226 you should also get current values. I am really curious if a different module will work, even if the issue is not related to my library. Good luck!

Regards, Wolfgang

Thank you for the great article!

Today I ran the first sketch using a INA226 breakout boards with R100 shunt. I hooked it up to a ESP8266 running on 3.3V.

The current results are great.

However, voltage is always around 20V, regardless of true input voltage. The reading doesn’t change even when I double or cut in half the input voltage.

Obviously I must be doing something really dumb. I double-checked the wiring and tested with a completely different INA226 board with R010 resistor.

With both boards, current reading is perfect (after adding the serResistorRange() call in the R010 case). Voltage reading however is always at around 20V fixed, with varying real loads and voltages.

What could I be doing wrong? Many thanks!

Do the module and the load have a common GND? That’s the only spontaneous idea I have.

Hi again,

I’m having a hard time understanding how exactly “using the smallest allowable Current_LSB” gives the highest resolution for the Current Register.

By Ohm’s law, the current resolution ultimately depends on the shunt voltage LSB, which is 2.5uV (fixed value), and the shunt resistor value. In other words, the current will increment in steps of shuntVoltage_LSB / shunt resistor. So for a 0.1Ohms resistor, the minimum detected current will be 25uA independently of whatever the “max expected current” is programmed.

I’m sure there is something wrong with my understanding.

So, anyway, for this module, if max expected current is only 0.2A, how is the current resolution increased? What will be the lowest measurable current in theory in that case?

Thanks

You are right, the ultimate limiting factor for the resolution of the measured current is the resolution of the shunt voltage register in combination with the shunt size. And your calculation is correct, 25 µA is the maximum resolution. With this, the maximum current is 0.8192 Ampere. Therefore, I have to admit that when using the 0.1 ohms shunt, there is no benefit in changing to the 0.4 amps range. I should take the option out. However, the calculations in the article shall show how to calculate the calibration factor.

Basically, one doesn’t rally need the current register. You can calculate the current yourself without all this stuff.

Hi, I just wanted to add I took out the range setting. It’s now 0.8192 volts. The reason why I had implemented the two ranges is simply that I first wrote a similar library for the INA219 where the ranges really increase the resolution. I just took this over. So, thanks for the comment. A new version 1.2.9 of the lib is now published on GitHub.

Best wishes, Wolfgang

Hello,

I’m noticing with all INA226 libraries a measurement error on the Bus voltage.

Here’s a table with the measured values:

Set (V) Max sensor reading(V)

0 0.03

0.5 0.51

1 1.02

1.5 1.53

2 2.03

3 3.05

4 4.06

5 5.08

10 10.15

15 15.23

20 20.3

25 25.38

30 30.46

35 35.53

ESP32 powering the device at 3.3V. Powering the sensor from an external power supply with voltages between 1.8V and 3.3V barely affect the readings (10mV max difference between 1.8V vs 3.3V supply).

The applied voltage on the Vbus pin is generated with a precise Riden RD6006P power supply and was checked with an Uni-T UT61D+ multimeter.

As you can see in the table, it’s almost a +1.5% constant error;

Have you experienced this with your sensor module? Any ideas what could be causing this?

Thanks

Hi Alejandro,

this is stange. I have just tried and have found a deviation of less than 0.1% between VBUS measured by the INA226 and my multimeter. I tested at 3.3 and 4.6 Volts. Have you tried different modules?

Hey, thanks for trying it out.

Unfortunately, I only have this module I got from AliExpress: https://ibb.co/CmNPTyK

It may be a fake chip, or just a damaged unit…

hi

Thank you for this Education

I have problem with uploading code in Arduino UNO

I downloaded your Code and library and try to upload this in to arduino UNO board

but Appears this error

Arduino: 1.8.19 (Windows 10), Board: “Arduino Uno”

Sketch uses 6908 bytes (21%) of program storage space. Maximum is 32256 bytes.

Global variables use 650 bytes (31%) of dynamic memory, leaving 1398 bytes for local variables. Maximum is 2048 bytes.

avrdude: verification error, first mismatch at byte 0x0800

0xff != 0x80

avrdude: verification error; content mismatch

avrdude: verification error; content mismatch

please help me to solve this problem

thank you

Parsa

This does not sound like an issue with my code, but something more general. Can you try to upload any other sketch like e.g. the blink sketch from the examples of the Arduino IDE? Does this work without failure?

Wolfgang

Dear Sir,

Thankyou for the reply. I am waiting for the 30A shunt to arrive from AliExpress. The one I have is 10A shunt. I will post my result here once the shunt arrives.

regards

sajeev

Dear Sir,

Thank you for the article. I am a newbie and don’t have much experience in electronics and poor in math. I am planning to use you continues.ino to measure the parasitic drain from a 12v car battery . I would like to measure with 1mA resolution form 0 – 30A range .Please advise what value of shunt resistor i should choose? I have one of those heavy shunts from aliexpress 75mv/A lying around. What is the range that can be measured with R100 shunt resistor originally installed on the module and what is the resolution>

regards

Sajeev

Hi, with the R100 (= 0.1 ohms) is 800 mA. The limiting factor is the shunt register. The current is calculated from the value in this register. The maximum shunt voltage is 81.9175 mV. If your maximum current is 30 amperes, the maximum shunt size is:

U = R * I (Ohm’s law)

R = U / I = 0.081975 / 30 = 0,0027325 Ohms

Are you shure that your shunt provides 75 mV / A? Usually these shunts provide 75 mV at the max. current. E.g. you can buy a 30A / 75 mV shunt. That would be a perfect fit because you would use almost the whole range of the module (75 mV vs. 81.975 mV).

https://www.aliexpress.com/item/4000064064917.html?spm=a2g0o.productlist.main.1.5c12612fsS9AkR&algo_pvid=bb39660a-d08c-4e03-9ae2-5ecadc648481&algo_exp_id=bb39660a-d08c-4e03-9ae2-5ecadc648481-0&pdp_npi=4%40dis%21EUR%212.50%212.38%21%21%212.62%21%21%4021038eda16941880101944247e5c90%2110000000289433251%21sea%21DE%21897358883%21S&curPageLogUid=Gg5Nz6w0VHWz

Be careful: 12V is not dangerous, but with 30A you can easily cause fire if your wires are too thin or the shunt is not correct!

And one additional comment: If you ony want to measure parasitic drain, then 30 amperes seems to very high.

Good luck, Wolfgang

Dear Sir,

Thankyou for the quick reply. I chose 30A range as the modules in the car wakes up intermittently and currant draw spikes to 10-15A and then drops to mA range. If i prepare the circuit only for mA these spikes may fry the 226board. I already ordered the aliexpress 30A shunt you linked above. What resolution can i expect? will I be able to measure 1mA with this 30A shunt?

Regards

Sajeev

Dear Sajeev, the values in the shunt register are the basis of all calculations. The resolution is 2.5 µV per bit and the register is +/-2^15 = +/-32768 which is roughly +/-82 mA. Your shunt delivers 75 mV at 30 A. That means you use 75/82 * 100 = ~91.5% of the range, which means ~ +/- 30000 bits in the shunt register. So, resolution is roughly 1 mA, so what you are looking for. However, this is an ideal value which does not consider any noise. To really get as near as possible to that resolution, you should average many values. I think the resolution will be in reality more in the range of few milliamps than 1 milliamp. But I would say, just try.

Regards, Wolfgang

Hello,

I am new in this arduino world. I have done a small proyect using your library. But I have the following problem. I have a circuit with two resistors in series, being the total sum of 1330 ohms, a LED and i am powering the proyect with 3.3V. Theorically the current i should get is 3.3/1330=0.00254A=2.54mA but i am getting a current of 1.11mA

Any idea of what could be wrong?

Thank you in advanced

Hi, you have two resistors and the LED in series, right? The LED also has a resistance. But its resistance depends on the current, so it’s a problem for the calculation. To just check if you get correct results, you could remove the LED. Do you then measure the calculated current?

Yes. I did what you said and now the result makes much more sense. I thought we could ignore the LED’s resistance but it seems to be high enough to take it into account.

Thank you for the post, it’s very useful for everyone that is trying to understand INA226.

Hi,

das ist sehr gut erklärt. Aber ich möchte 2 oder 3 ina226 zusammen schalten und aus lesen. Leider bekomme ich es nicht hin. Gibt es so etwas im Netz oder wo finde ich eine Erklärung?

Gruß

Lorenz

Hi,

hier bist du auf der englischen Seite gelandet. Das gibt’s auch auf Deutsch. Aber kein Problem.

Erst einmal muss jeder INA226 hardwarseitig seine eigene I2C Adresse bekommen. Das habe ich im Beitrag erklärt. Du verbindest dann alle SCL Pins und alle SDA Pins. Über die I2C Adresse wissen die Module, welches von ihnen angesprochen wird.

Dann erzeugst für jeden INA226 ein eigenes Objekt:

INA226_WE ina226_1(0x40);

INA226_WE ina226_2(0x41);

INA226_WE ina226_3(0x44);

Dann musst du für jedes einzelne die Einstellungen vornehmen:

ina226_1.init();

ina226_2.init();

ina226_3.init();

ina226_1.setMeasureMode();

ina226_2.setMeasureMode();

….usw.

Und dann in loop():

shuntVoltage_mV = ina226_1.getShuntVoltage_mV();

busVoltage_V = ina226_1.getBusVoltage_V();

…usw und dann zeigst du die Werte auf dem seriellen Monitor und gehst zum nächsten INA226:

shuntVoltage_mV = ina226_2.getShuntVoltage_mV();

busVoltage_V = ina226_2.getBusVoltage_V();

…..und dasselbe für Nr. 3. .

Ein bisschen verschwenderischer wäre die Variante:

shuntVoltage_mV_1 = 0.0; shuntVoltage_mV_2 = 0.0; shuntVoltage_mV_3 = 0.0;

shuntVoltage_mV_1 = ina226_1.getShuntVoltage_mV();

shuntVoltage_mV_2 = ina226_2.getShuntVoltage_mV();

…usw..

Prinzip klar geworden?

VG, Wolfgang

Sorry hab ich nicht gesehen. Hat sich überschnitten. Danke für die schnelle Antwort. Ich hab keinen Fehler gefunden. Bin aber auch kein Profi.

Lorenz